In a time where efficiency and quality are paramount, automation has become a crucial element in the industry. Recently, Hans, our consultant, participated in an engaging training at Actemium Open College on industrial automation, gaining insights into the complex world of manufacturing processes and automation technologies. We invest in this knowledge to better interpret the needs of our clients. This allows us to make a qualitative difference compared to companies that merely recruit based on keywords.

What does a manufacturing company entail?

Every manufacturing company faces a wide range of challenges and processes, from procurement and planning to production, quality control, and sales. During the training, Hans learned that managing resources, raw materials, and finished products, along with compliance with regulations, is essential for the success of a manufacturing company. One of the key insights we gained is the understanding of different types of processes, such as continuous, batch, discrete, and combination processes, each with their own unique characteristics and applications within the industry. The training also covered important aspects such as automation levels, machine safety, food safety, pharmaceutical regulations, and traceability.

The importance of traceability and standards

One of the topics emphasized during the training was traceability and why it is essential for manufacturing companies. Traceability enables companies to accurately track products through all stages of production, processing, and distribution. This not only increases safety and quality but also meets legal requirements and reduces product loss. Furthermore, the importance of using industry standards, such as ISA-88 and ISA-95, for design, process modeling, programming, and documentation, as well as the role of new technologies such as IIoT, robotics, and big data, were discussed in pursuit of more efficient operations, improved quality, and sustainability.

Industry trends

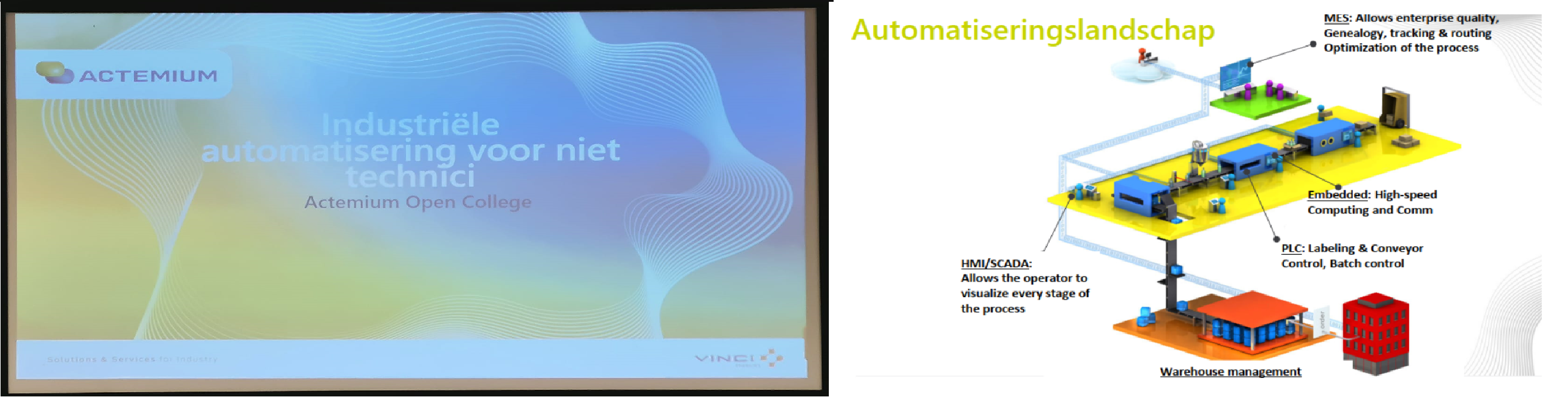

This training also highlighted various trends in the industry, such as production resources, information flows, and the evolution of Manufacturing Execution Systems (MES), all aimed at improving production capacity, definitions, and outcomes. Finally, various levels of automation were discussed, from PLCs and SCADA to MES, and how they contribute to a more efficient and streamlined production environment.

Do you want to contribute as an expert to the world of Automation in NL?

Do you have a deeper understanding of the complexity and possibilities of industrial automation? Do you understand how to apply these concepts to optimize processes, improve quality, and meet the ever-changing demands of the industry? If you are interested in collaborating with us, please contact us or check out the vacancies on our website for any exciting opportunities.